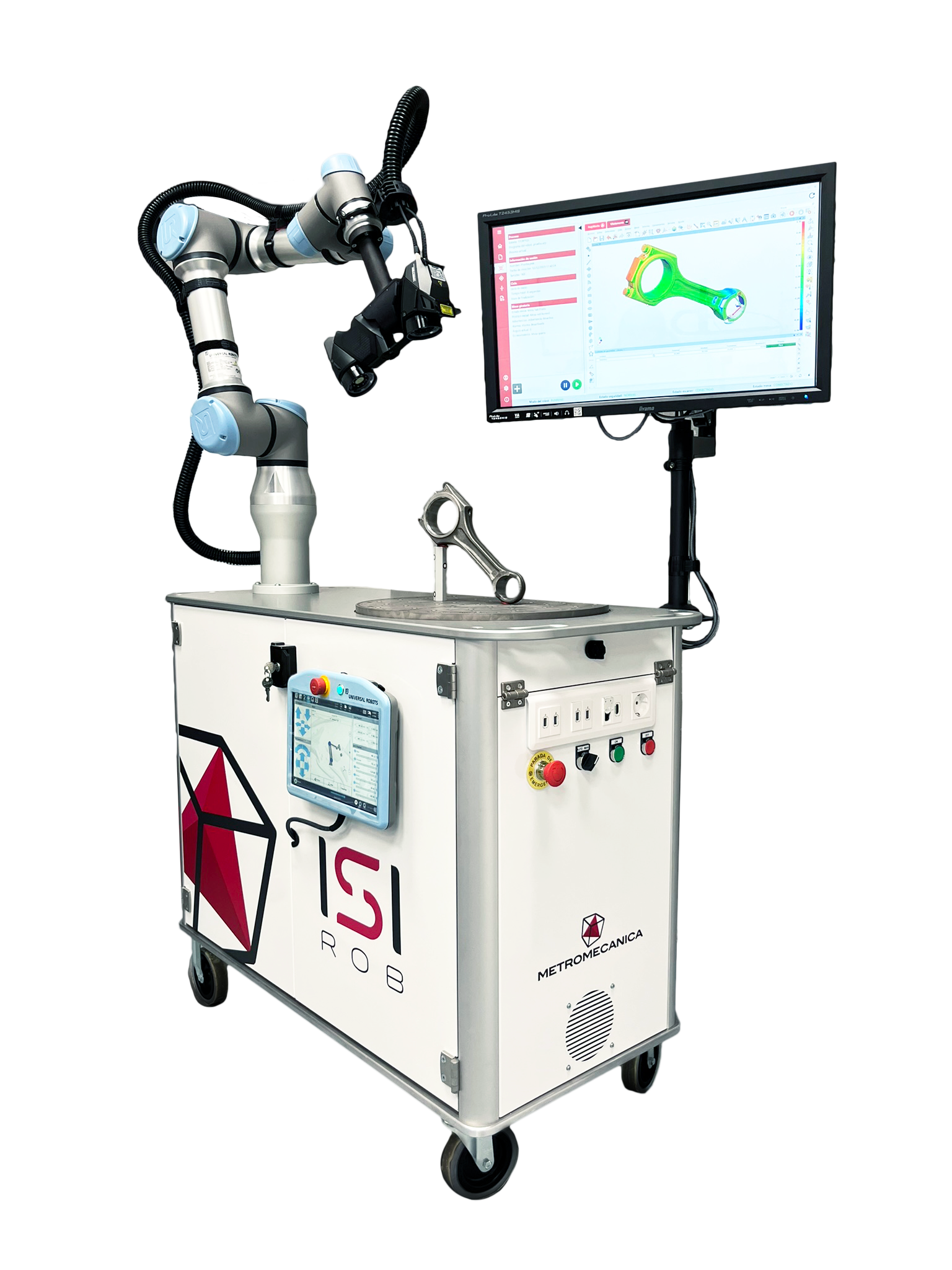

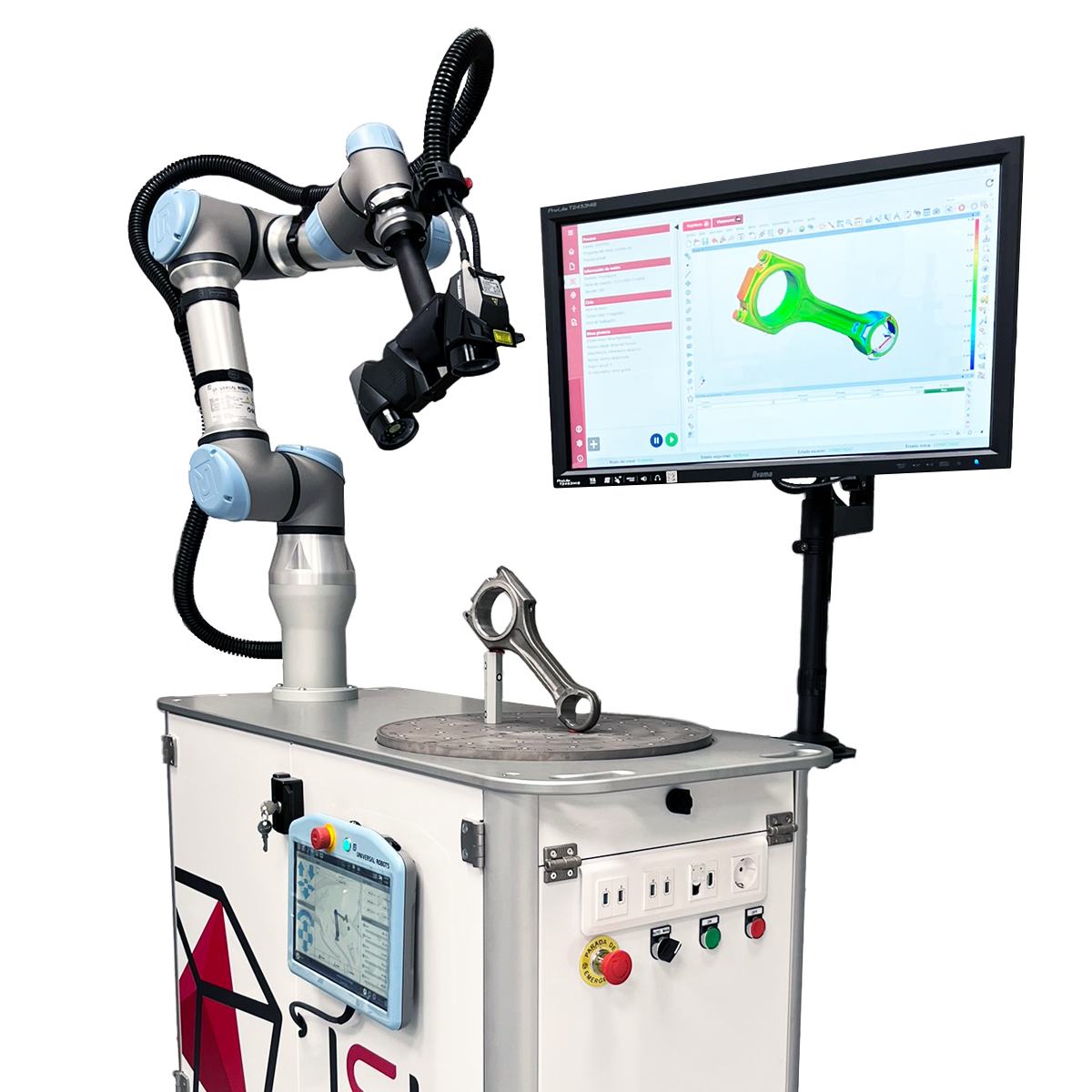

ISI ROB is an automatic 3D measurement system created by Metromecánica, designed to carry out the dimensional inspection of products and parts on the shop floor in the simplest way.

Discover the benefits of ISI ROB

- Simple to use, no expert metrology technicians are required.

- Non-specialists can inspect parts and obtain full 3D dimensional reports instantly.

- The ISI ROB system can be installed at the production line, no laboratory conditions are required.

- Simple to use, no expert metrology technicians are required.

- Possibility of programming multiple references.

- Statistical production control capacity, obtaining data in real time.

Why ISI ROB is the best solution to optimise your measurement processes.

- - For single use by reference.

- - With important delivery and adjustment deadlines.

- - With a high cost of design, manufacture, calibration, maintenance and storage.

- - Values are limited to contact areas and traceability can be improved.

- - These are saturated.

- - They need to be operated by metrology technicians.

- - They are located in dedicated laboratories.

- - The results are not immediate.

- - Dimensional analyses require massive data for their analysis.

- - Surface colour maps are current demand.

With the ISI ROB solution, you will find the dimensional inspection partner you have been waiting for.

We have created a measurement solution composed of:

- Creaform handyscan model state-of-the-art scanner.

- UR5 collaborative robot.

- Servo-motorised rotary table.

- Agile 3D automation software.

- PolyWorks metrology software.

- Mobile cart: integrates and connects components.

AGILE 3D, ISIROB's control software, which allows non-expert technicians, with a basic one-day training, to complete the programming of new references in minutes so that, subsequently, workshop operators can carry out the measurements following a simple and intuitive 4-step guided sequence.

Features Technical

3D scanning sensor Creaform Handy Black Elite Accuracy: 0.025 mm

Scanning speed: 1,300,000 pnt/sg

Scanning area: 310 x 350

Range of 850 mm Repeatability +/- 0.1 mm Protection IP54.

Workstation with point cloud processing capability

Intuitive user interface, allows measurement with simple touch screen commands.

Robust component integration on a mobile trolley. Total weight: 240kg.

Automation Software: Agile 3D.

It enables simple and intuitive control of peripherals, simplifies tasks and reduces programming times.

Available with 3D metrology software:

Maximum inspection volume:

600 x 600 x 750 mm

4 USB ports. HDMI. Ethernet network port. 220 V power socket. Emergency buttons.

Rotary table with

repeatability ±2 arcsec.

Maximum weight 100 Kg